In the evolving landscape of oilfield solid management systems (SMS), our modular high-pressure Sand Filter and Desander (SFDS) system represents a significant advancement. The SMS market has been profoundly impacted by the current low oil price environment, compelling operators and service providers to navigate economic constraints, time pressures, and heightened competition while addressing increasingly complex work scopes. Consequently, there is a pressing need for innovative SMS tools that can adapt to these challenges. The design ethos of the SFDS is centered on four key principles: maximizing equipment performance and performance envelopes; enhancing flexibility and configurability; simplifying ease of use during rig-up/down operations, configuration changes, and maintenance; and minimizing equipment inventory requirements. This comprehensive approach ensures that operators can optimize their workflow while maintaining operational efficiency in a demanding industry.

At MSES, our personnel are at the heart of our success. With extensive experience in the field, they execute every job with the utmost focus on safety, efficiency, and accuracy, ensuring the reliable delivery of well test data. Additionally, our Sand Management System has proven its effectiveness under the harshest conditions in Saudi fields, consistently delivering optimal performance even in demanding environments. We are committed to providing high-quality, reliable, and innovative solutions that meet the needs of the oil and gas industry. Our 10,000 Psi Twin Pot Sand Filter Package is engineered to enhance well test operations by effectively removing drilling, formation, and proppant-based solids from wellbore fluids. This filtration system minimizes the risk of damage to downstream pressure control and measuring equipment, which is critical for maintaining operational integrity and safety during drilling activities. The design emphasizes reliability and efficiency, ensuring that the filter operates optimally under high-pressure conditions.

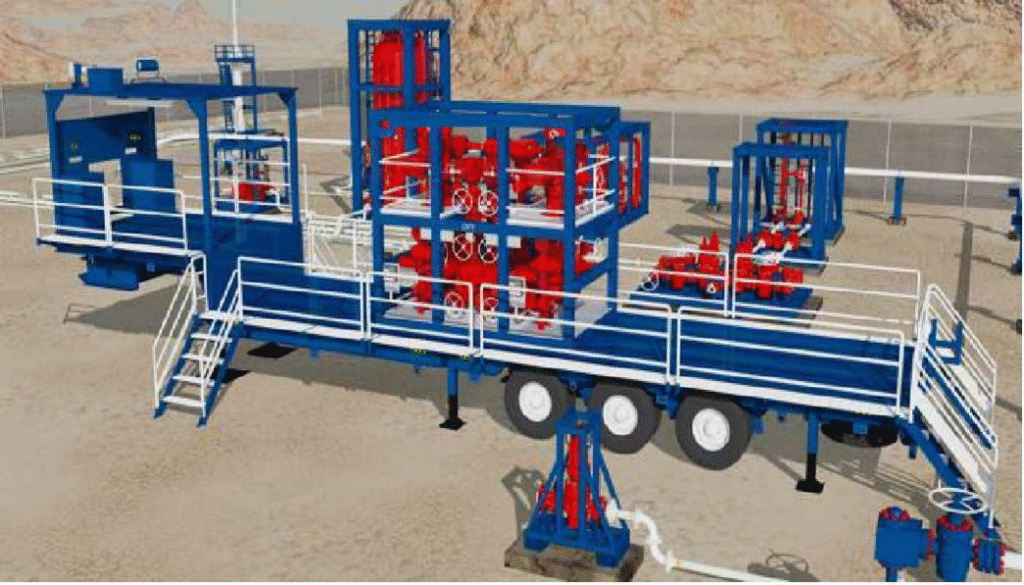

This package is housed in a 20ft ISO CSC and DNV 2.7-1 certified container frame, allowing for standardized deployment across both onshore and offshore applications. The modular design facilitates skid mounting or direct integration onto mobile trailer units as needed. Furthermore, the inclusion of explosion-proof lighting in both working areas enhances safety by providing adequate illumination during operations.

To support effective monitoring and management of the filtration process, an instrumentation package featuring analogue pressure gauges and an electronic differential pressure system is integrated into the design. Additionally, safety measures such as a full drip pan with drainage outlets and galvanized grating ensure a secure working environment around the vessels.

The upper working area features recessed access with ladders at either end and removable safety handrails for improved ergonomics compared to traditional sand filter frames. An integrated crane beam equipped with manual or pneumatic chain block hoists further facilitates maintenance tasks by allowing easy removal of vessel components. Moreover, a lockable toolbox provides essential storage for tools necessary for efficient operation.